Deposit

Gabbro-diabase – gabbrodolerit, a volcanic rock .

Today, gabbro-diabase is mined in three regions: Ukraine, Australia and Karelia, but it is possible that gabbro-diabase production may be initiated in other countries or regions of Russia in the future.

Karelian gabbro-diabase is produced in Karelia, the largest developed field is located in the vicinity of the village of Drugaya Reka, so most often we meet with Drugoretsky gabbro-diabase, but in Karelia there are other gabbro-diabase deposits that are being mined or are planned in the near future. For example, the field of the Rop-Ruchey ridge near the village of Shoksha or the fields of the northern regions. So, for example, the Karelian Granite Company is the owner of the absolutely black gabbro deposit in the Louhsky district, not far from the village of Kestenga. Gabbro here has a completely black color, an analog of Chinese black granite, often the blocks of this deposit are called “Rombak” or “Karelia black”.

The quality of the extracted stone is evaluated according to the standard requirements specified in GOST for rock blocks: shape, size, and absence of cracks. Directly at the quarries, the blocks are sorted and sent to factories for the production of gabbro-diabase products.

The specifics of the crack system of the Drugoretsky field are such that the most optimal and effective way to extract gabbro-diabase blocks here is the drilling and blasting method. At the field near Shoksha, this method is also used, but in the northern regions of Karelia, production is carried out by rope sawing.

Characteristics of gabbro-diabase deposits in Karelia

A stone of igneous origin, characterized by a rich granular structure and subtle shades. The geological age of the rock is more than 2.5 billion years, while the closest analogues of gabbro-diabase are less than 1.5 billion years old. Gabbro-diabase differs from granite in that it was formed from magma poor in silica, while granite, on the contrary, is formed from magma rich in silica. Silica is a characteristic of the presence of quartz in gabbro-diabase, so granite contains quartz, but gabbro-diabase does not. Granite consists of: quartz, feldspar and mica. And gabbro-diabase is mainly composed of plagioclase and pyroxene.

Partially, this is why gabbro of Karelia has a number of advantages: high strength and density, which made gabbro-diabase absolutely not absorb water, the stone can get wet, but it does not let water inside, so even if it freezes after rain it will not crack and ice crusts will not form on the surface.

The strength of gabbro-diabase is so high that it can be used in any area of construction, including for the construction of railways and airfields.

Physical and mechanical properties of gabbro-diabase of Karelia

A distinctive feature of the stone is a high level of hardness, strength of 1400 kg / cm2, this quality guarantees its resistance to loads.

Water absorption of gabbro-diabase is 0.1%, the stone is almost 100% moisture resistant. It does not collect water, which guarantees its resistance not only to frost, but also to sudden temperature changes.

Abrasion resistance-0.07 g / cm2. This means that when a flow of 1 million people passes over the surface from gabbro-diabase, the paving will be worn by less than 0.12 mm. For comparison, marble will wear out 100 times faster, and any other granite 10 times.

Gabbro of Karelia accumulates and gives off heat well, so it is used as a stone for bath stoves.

For the longest time of all known breeds, it does not lose its artistic properties and the quality of polishing.

It does not fade in the sun, after tens or even hundreds of years, it does not get spots or other defects of the surface. Therefore, it is absolutely practical and does not require additional care.

With all this, it is perfectly amenable to any type of processing: cutting, heat treatment, bush hammering, polishing, engraving.

For hundreds of years, it preserves its engraving and polishing quality, which is why it has established itself as the best black granite for the production of monuments, memorials and art panels from gabbro-diabase.

It is very important to note that gabbro-diabase of Karelia is absolutely not radioactive, it belongs to the first class building materials and can be used for interior decoration, among other things.

In addition, Karelian gabbro-diabase does not emit harmful impurities at all, even when heated or frozen, it is resistant to chemical reagents, so we can safely say that Karelian gabbro does not harm the environment and is an eco-friendly building material.

Types of processing

We produce products of any complexity from gabbro-diabase. With the following ways of processing:

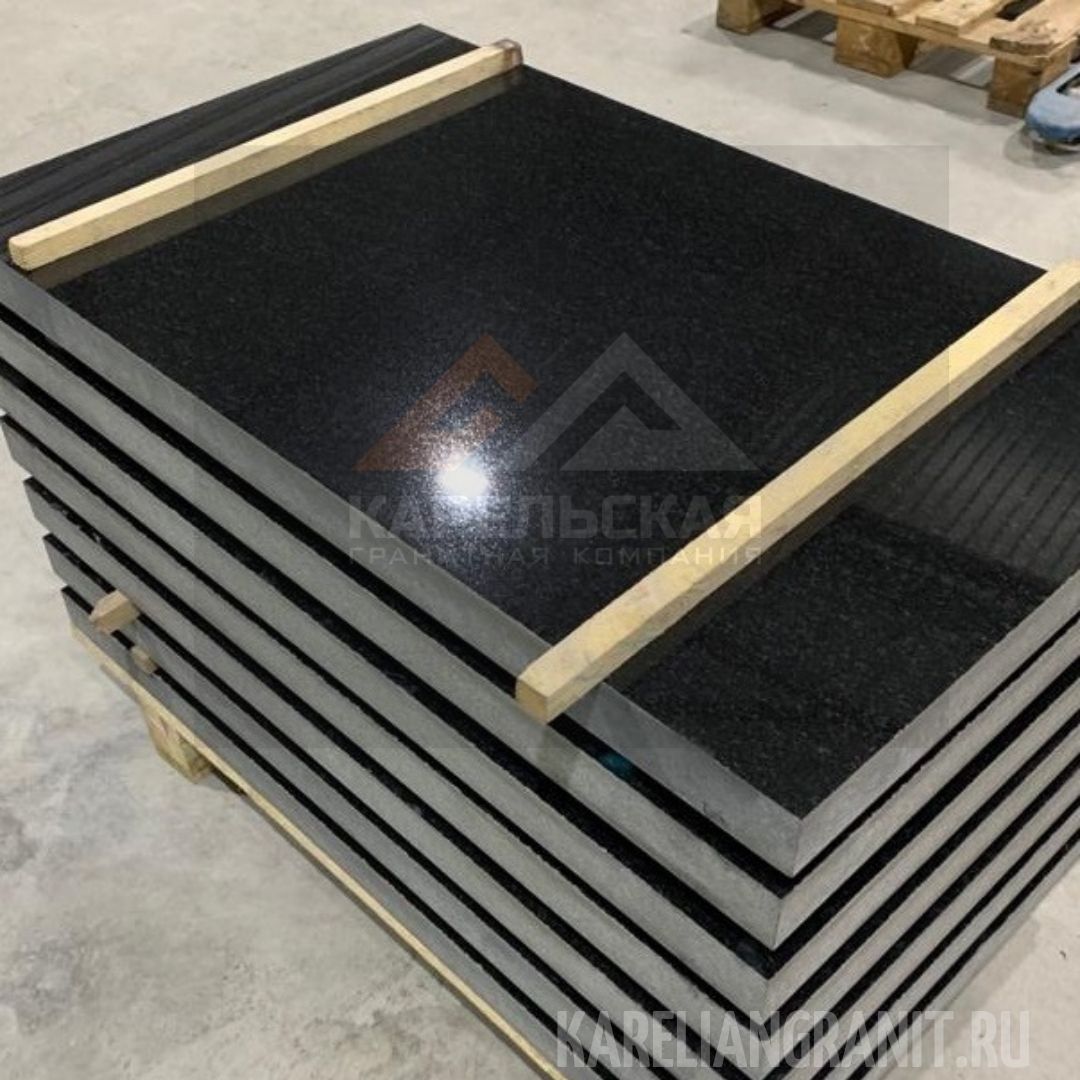

Polished gabbro diabase:

Before polishing, gabbro-diabase has a gray color, after polishing it takes on a color from dark gray to charcoal black.

However, on the surface of gabbro-diabase, light accumulations of plagioclase are always present and will be visible.

The color of the polished surface of the product will differ depending on the prevailing color of the minerals in the composition: light or black.

At the same time, it should be taken into account that the presence of light minerals in gabbro determines not only the color of the stone, but also its fracturing. According to the observation of many specialists of stone processing, the higher the content of a light mineral in granite, the less fractured it is, the more it is resistant to aggressive environments and temperature changes.

Visually, gabbro-diabase will look darker with high-quality polishing. Even the “gray” gabbro-diabase will look black and uniform if the required polishing depth was achieved during the processing.

Gabbro-diabase heat treatment:

Heat treatment or fire treatment of gabbro-diabase is done in order to give the granite additional roughness.

The surface is exposed to fire with a temperature of up to 2500 degrees, as a result of which unstable and brittle minerals are removed from the surface. Due to this, the surface gets a rough relief and increases the anti-slip effect.

Gabbro-diabase bush hammering

In addition to heat treatment, to give roughness and achieve an anti-sliding effect, another processing method is also used — bush hammering. With the help of a special tool, which is called a bush hammer, the granite is processed with shock-rotational movements. At the same time, the “roughness” is achieved deeper than during fire treatment, which provides the surface with even higher adhesion qualities.

Split and tumbled gabbro-diabase

Obviously, a useful quality of gabbro-diabase is that it is very well split. Therefore, crushed paving stones from gabbro Drugoretsky turn out to be more or less smooth, which is an important indicator for laying and further operation.

Another type of processing can be also mentioned — tumbling. By placing the “cubes” of gabbro diabase in a special drum-centrifuge, the output is a tumbled paving stone, which today is popular and has found its wide application.

Areas of Application

Due to its properties, the stone is in high demand in various fields.

In Russia, 80% of this is the ritual sphere: monuments and landscaping around them.

In second place are the paving stones and paving of the streets. Gabbro-diabase can withstand exorbitant loads. The coating of it does not explode in the cold and has a negligible abrasion.

It is used in interior solutions: countertops, steps, and other elements.

Environmentally friendly, with a low radiation background, it is absolutely safe for indoor use.